CNG pressure relief device

CNG pressure relief device

CNG pressure relief device

- Detail

- Parameters

Gas supply station release device process description

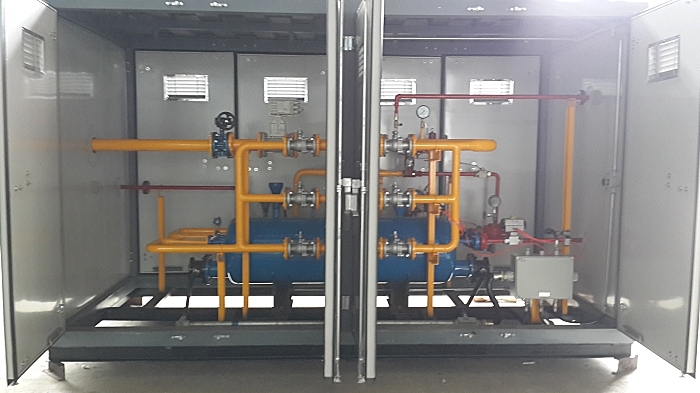

First of all, use the car head to pull the car full of compressed natural gas pry to the gas supply station, connect the highpressure hose on the unloading platform with the CNG pry, and through the highpressure pipeline, the natural gas enters the release device. After entering the release device, the natural gas goes through the filter first and is heated by the stage heat exchanger. The heated natural gas is adjusted to 1.6mpa by the stage pressure regulator, and then enters the stage pressure regulator to adjust the pressure to the required pressure. In the process of heat exchange and pressure regulation, it has low temperature protection of natural gas, primary outlet pressure overpressure protection (overpressure cut-off and ~ release), and pressure overpressure protection (overpressure cut-off and ~ release) after the outlet of the release device. Compressed natural gas enters pipe network after pressure regulating by release device, metering and deodorization.

The performance of voltage regulator and insulometer

Double entrance two channel configuration, using one open and one standby form, each channel is independent of each other, when necessary, two channels work at the same time. There are two stages of decompression and two stages of heat exchange in each circuit. Two stages of decompression ensure that the decompression distribution is reasonable and stable. Two stages of heat exchange ensure that the temperature of compressed natural gas in the decompression process is about 5°C. - The pre-exit pressure grade of grade I voltage regulator is 25 MPa. - The outlet pressure of stage voltage regulator is 1.6~ 2.0 MPa, and the outlet pressure of stage voltage regulator is 0.1 ~ 0.4mpa (or according to user needs), because the working pressure of compressed natural gas pressure regulator and metering device is relatively high (20MPa). , and the pressure variation range is large, so the rationality of the structure of the pressure regulating and metering device is strictly required, and the reliability of the material selection of the pressure regulating and metering device is fully considered. HXR/CNG pressure regulating and metering devices produced by the unit adopt redundant design in operation to ensure the realtime and reliability of signals, with automatic pressure regulating, automatic cutting and automatic alarm functions. The main entrance with emergency cutoff valve, to achieve every occurrence of any fault, immediately cut off the inlet air source, to ensure the personal and pressure regulating device. Each one-level pressure regulating valve is cut off and twolevel overpressure is released. The control adopts doubleway redundant alarm chain to ensure the operation of the whole device.